|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Mondial Sportrack Manual Lymphatic Drainage Systems

- Mondial Sportrack Manual Lymphatic Drainage Machine

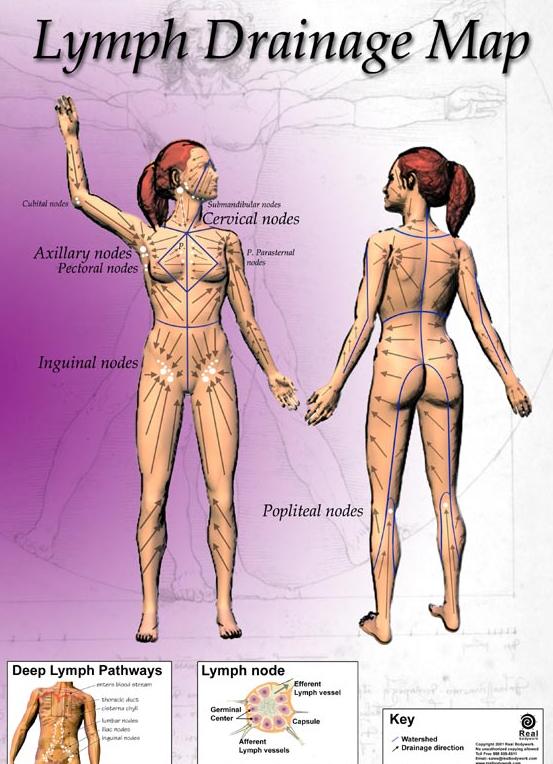

- Manual Lymphatic Drainage (MLD) History

VODDER’S MANUAL LYMPH DRAINAGE in 1967. Wittlinger and Vodder also founded the very first Dr. Vodder School in 1972 in Walchsee – Austria. In Europe, MLD has since grown to become a widely used and reimbursable physical therapy technique. It is the most prescribed and reimbursed physical therapy in Germany. 1st edition The Lost Continent: Travels in Small-Town America is a book by travel writer, chronicling his 13,978 mile trip around the United States in the autumn of 1987 and spring 1988.

| HOME | About us | PCBN insert | PCD insert | Site map | Contact us | Technical FAQ |

PCD insert | |||||

| CCGW/CCMW0602 | CCGW/CCMW09T3 | CCGW/CCMW1204 | CPGW/CPMW0602 | CPGW/CPMW09T3 | CPGT/CPMT09T3 |

| CCGT/CCMT0602 | CCGT/CCMT09T3 | CCGT/CCMT1204 | CPGT/CPMT0602 | ||

| DCGW/DCMW0702 | DCGW/DCMW11T3 | DPGW/DPMW0702 | DPGT/DPMT0702 | DPGW/DPMW11T3 | DPGT/DPMT11T3 |

| DCGT/DCMT0702 | DCGT/DCMT11T3 | ||||

| TCGW/TCMW0902 | TCGW/TCMW1102 | TCGW/TCMW16T3 | TPGW/TPMW0902 | TPGT/TPMT0902 | TPGX/TPMX1103 |

| TCGT/TCMT0902 | TCGT/TCMT1102 | TCGT/TCMT16T3 | |||

| VBGW/VBMW1604 | VBGT/VBMT1604 | VCGW/VCMW1103 | VCGT/VCMT1103 | VCGW/VCMW1604 | VCGT/VCMT1604 |

| WCGW/WCMW0402 | WCGT/WCMT0402 | WCGW/WCMW06T3 | WCGT/WCMT06T3 | ||

PCD insert | |||||

Mondial Sportrack Manual Lymphatic Drainage Systems

Mondial Sportrack Manual Lymphatic Drainage Machine

.png)

We export PCBN insert to world wide countries, such as USA united states, Germany, UK united kingdom, Italy, France, Turkey, Russia, Saudi Arabia, United Arab Emirates, Ukraine, Israel, Canada, South Africa, South Korea, Japan, Australia, New Zealand, Finland, Sweden, Norway, Danmark, Switzerland, Poland, Czech,Ireland, Holand, Belgium, Greece, Croatia, Spain, Portugal, Egypt, India, Philippines, Cambodia, Thailand, Malaysia, Singapore, Indonesia, Mexico, Brazil, Colombia, Chile, Argentina etc. |

Manual Lymphatic Drainage (MLD) History

| Contact: Richard | Tel: +0086-13929967797 | E-mail: sales@pcd-insert.com |